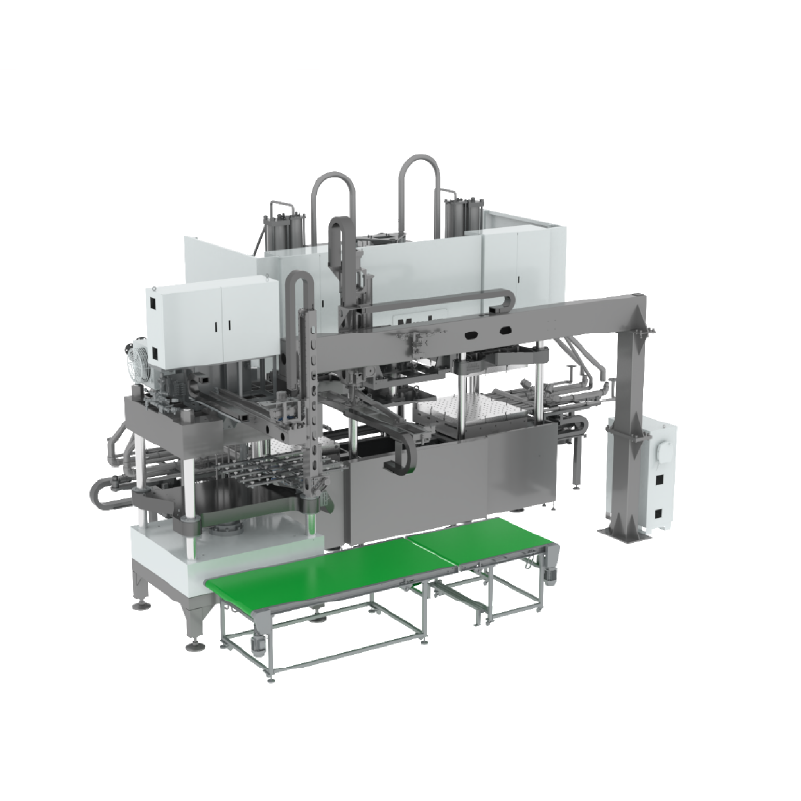

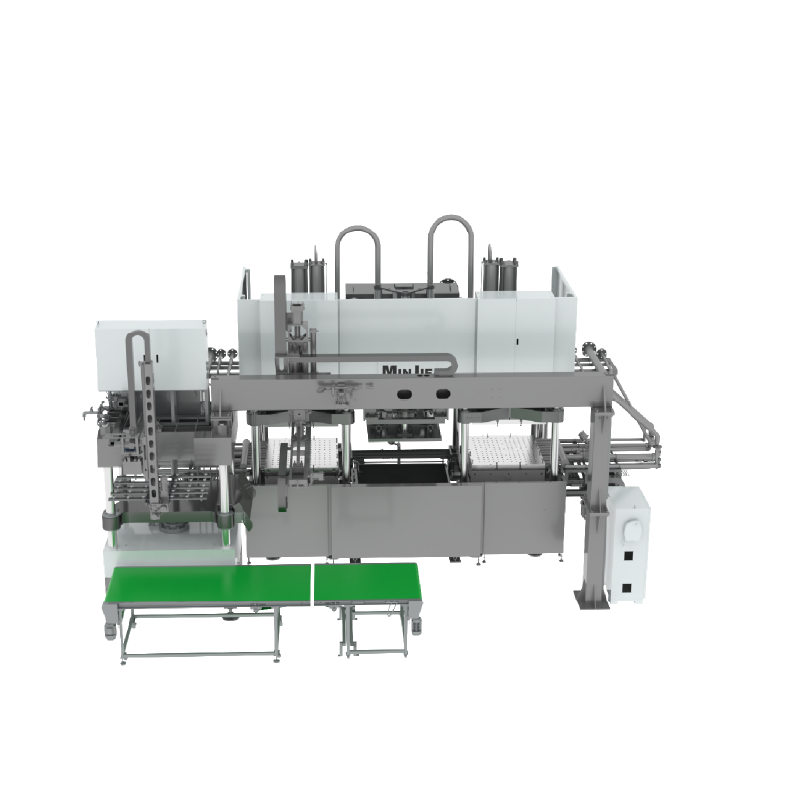

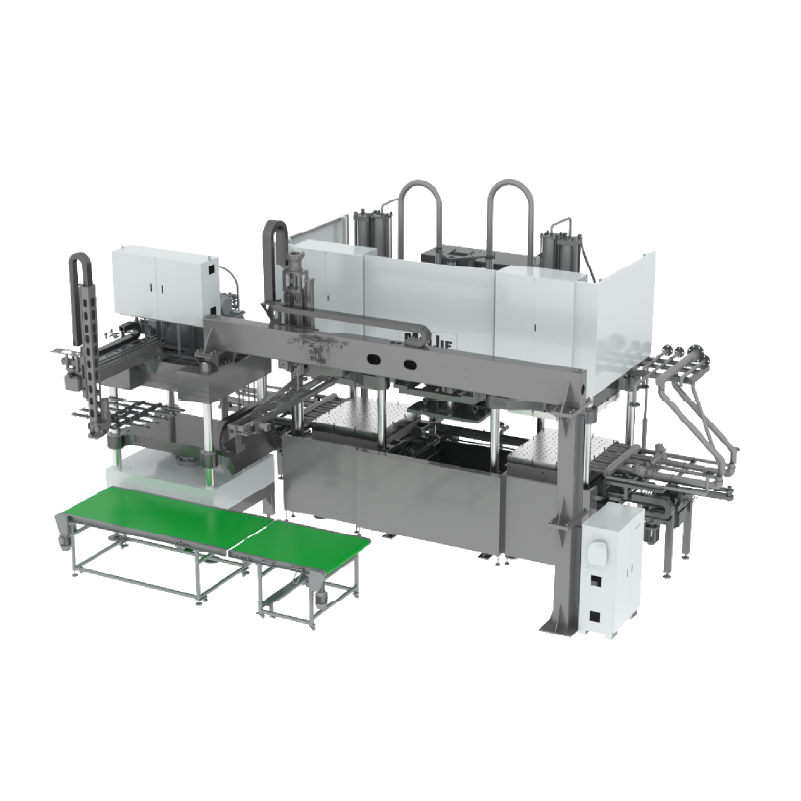

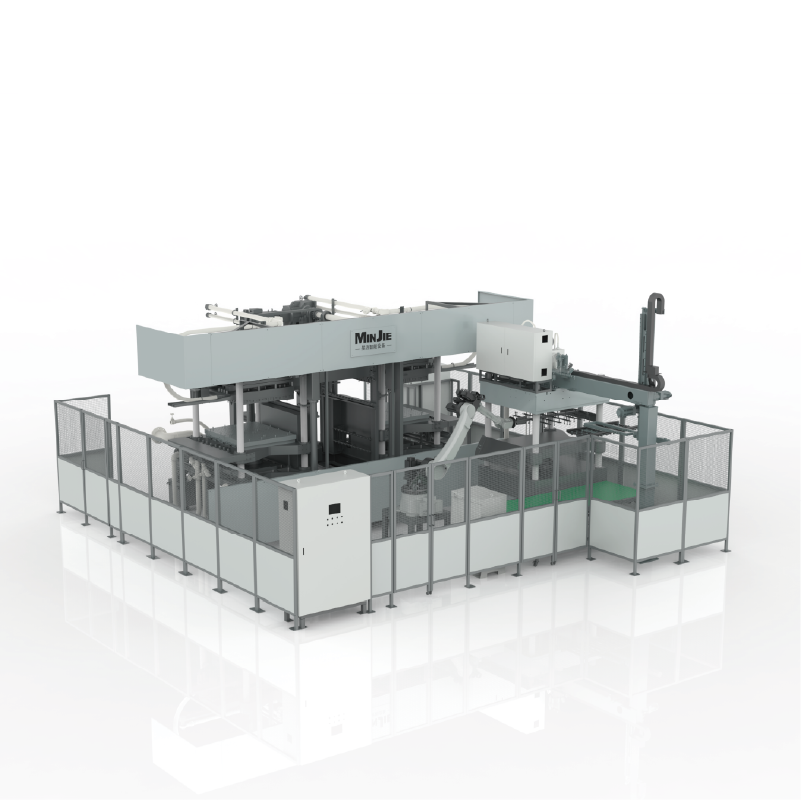

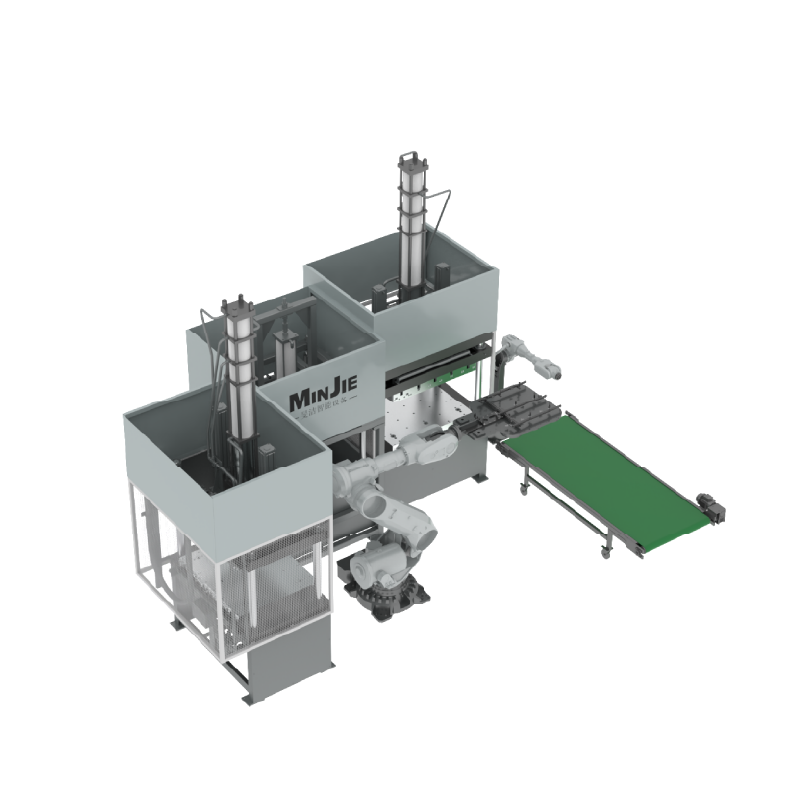

Full Automation Molded Fiber Tableware Machine MJDTN121-1210C

Type:

Structure: dig forming, two hot-press working stations and in-line trimming, and with no need to match with transfer mold to move wet product from forming station to hot-press station(s), beneficial to being higher in precision and more energy.

Leave Message

Equipment introduction

| Item | Technical Parameter |

| Platen size | 1200mm*1000mm |

| Structure | Suction Forming + Heat Press(two stations) + Trusser + Online Trimming |

| Heat Power | Thermal OilHeating or Electrical Heating |

| Rated Power | 6kw(thermal oil heating) or 166kw(electrical heating) |

| Outer Size | 9500mm*5200mm*4200mm |

| Weight | 25.5 tons |

| Average Output | 780-1000kgs/day |

| Vacuum Setting | 23-25 m³/min |

| Air Setting | 3-4 m³/min |

| Forming Type | Dig Suction |

| Main Drive | Servo(Suction Forming) + Pneumatic(Heat Press) + Hydraulic(Trimming) |

| Feature | Capable of making food packagings with General design or designs with fit sealing functions |

Equipment advantages

| Processing Point | Drive Method |

| Suction Forming Work Station | Servo Motor+Precision Reducer |

| Heat Press Station | Pneumatic (Air-liquid Booster, 60 tonnage Force) |

| Trusser | Servo Motor+Precision Reducer |

| Trimmimg Work Station | Hydraulic (Hydraulic Servo,60 tonnage Force) |

| Stacking/Conveyor/Trusser Mechanism | Servo Motor+Precision Reduce |

| Wet Product Transfer (Suction Forming-->Left Heat Press) (Suction Forming-->Right Heat Press) | Servo Motor+Precision Reduce |

| Processing point | Parameter/Feature |

| Stiffness | adopting rack structure, increasing the overall machine stiffness |

| operation accuracy | adopting full mechanical structure to ensure accuracy |

| operation safety | based on CE requirement |

| pipeline design | optimized pipeline layout which makes the processing with higher stability |

| mold maintenance | with relatively low heating temperature (160-180℃) which lengths the hole-cleaning duration, and with reasonably long mold cleaning period. |

| machine maitenance | reasonable and user-friendly design which makes it easy to do maintenance |

| Machine | Warranty Service | Component Description |

| Tableware Machine | 3-year Warranty | Machine Racks, Upper Platen, Down Platen, Pulp Tank, ect. |

| 1-year Warranty | Guiderails, Sliding Blocks, Cylinders, Pneumatic Components (not including push-in fittings, sealing parts), reducers, motors, electrical components, ect. | |

| Weary Part (Out of the warranty range) | Buttons, push-in fittings, vacuum skeleton hoses, sealing parts, heat insulation plates, ect. |

Equipment Video

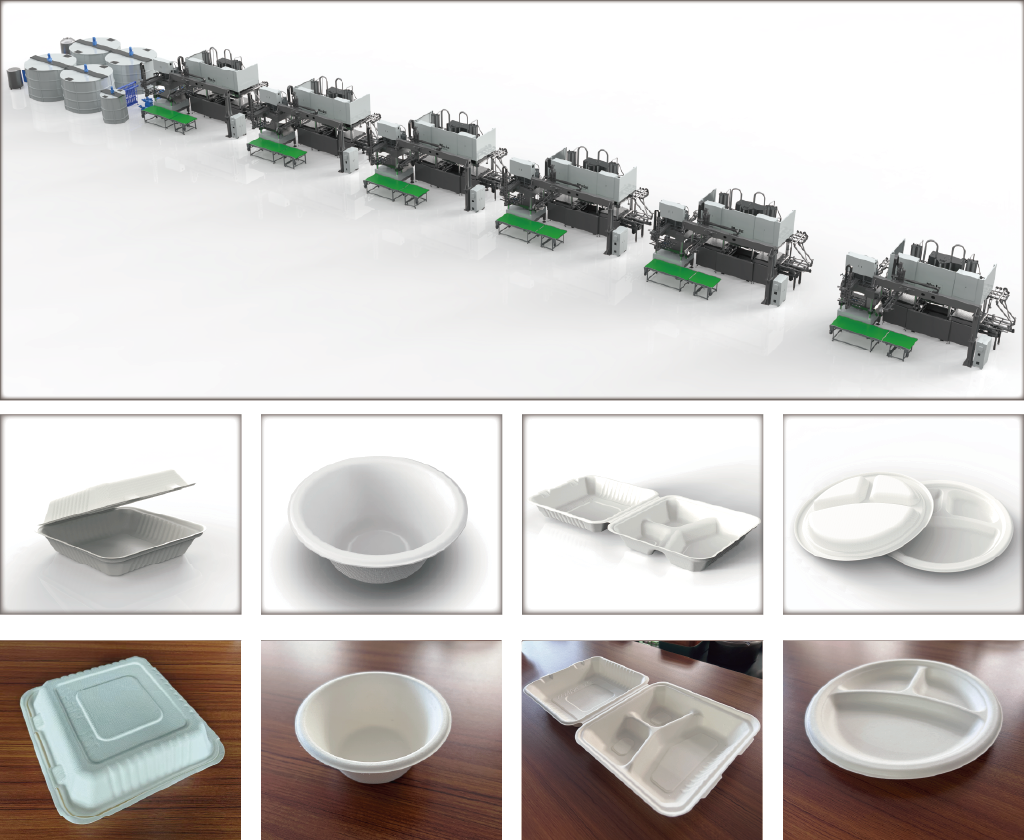

| Description of the video: Here you can see the full automation fiber molding food container making machine with molded fiber 9 inch clamshell food packaging being produced and an daily output of 800 kgs (based on 32 seconds per drop as the running speed, with online trimming involved, using a trusser to pick up half finished packages in a cost-competitive way) It is a cutting-edge automated pulp based molding tableware machine with high-speed, precision manufacturing. |

| Core Strengths: Performance: Delivers high output with exceptional forming accuracy and consistent, reliable operation. Design: Features a robust, modular build that simplifies maintenance and supports future upgrades. Efficiency: Reduces labor costs and minimizes operational risks through advanced automation. |

| Materials & Products: Sustainable Inputs: Utilizes plant-based fibers like bagasse, bamboo, wheat straw, reeds or palmae. Versatile Output: Produces bowls, plates, cups, lunch boxes, hamburger containers, and high-quality customized food containers. |

Product Applications

Representative Case

Keywords:

Molded Fiber Tableware Machinery

pulp molding tableware machine

molded pulp tableware machine

Leave a Message

HOW CAN WE HELP YOU!

We understand the importance approaching each work integrally and believe in the power of simple and easy communication.

Relate Product

Minjie Eco-Machinery Technology Co., Ltd.

Factory

Tangxia Town, Pengjiang District, Jiangmen City, Guangdong, China

Operation Center

Lihe Science Park, Shishan Town, Nanhai District, Foshan City, Guangdong, China