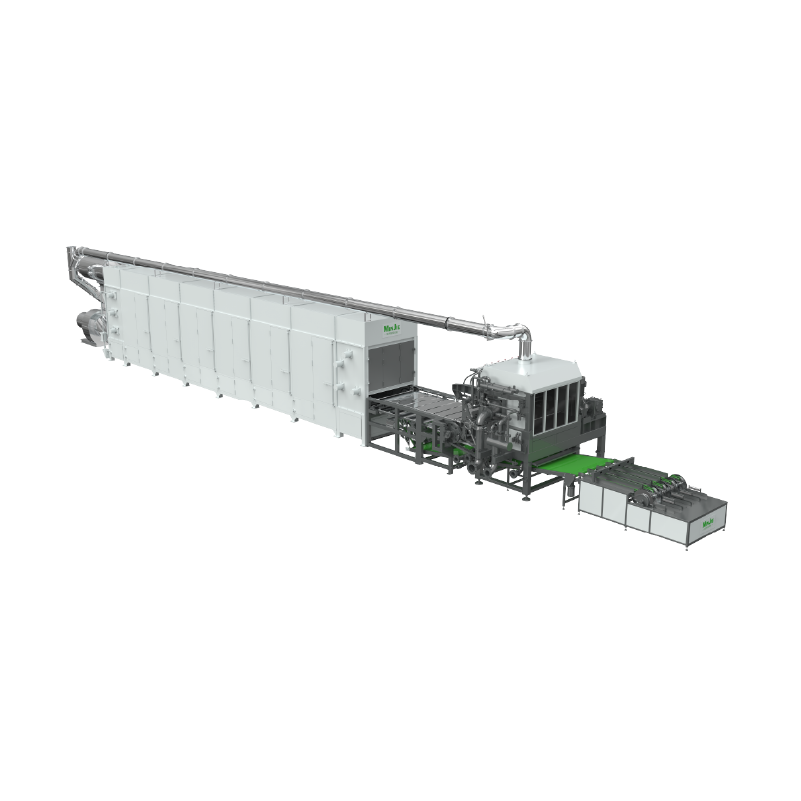

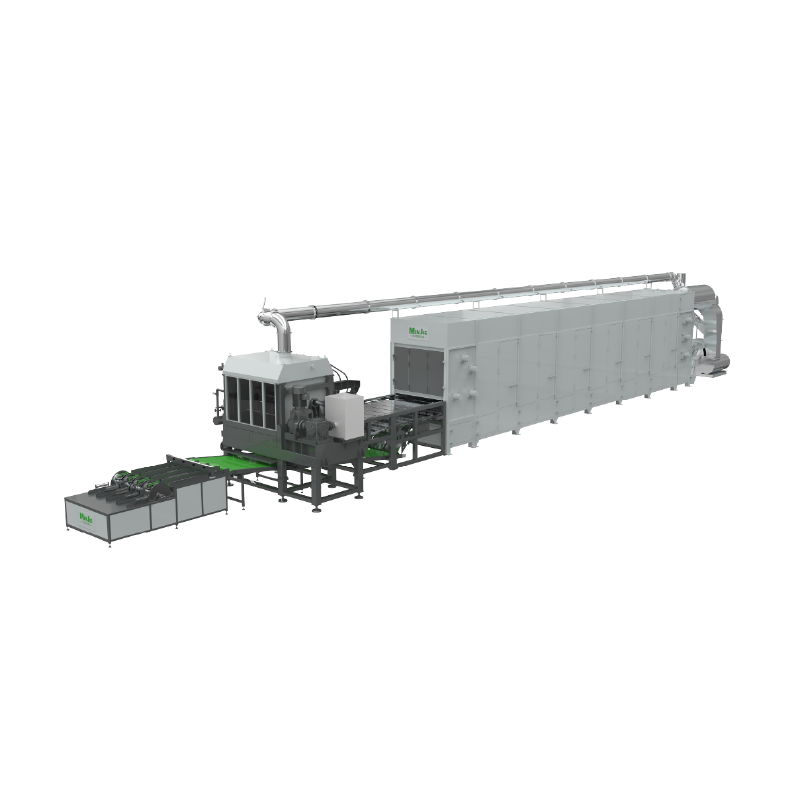

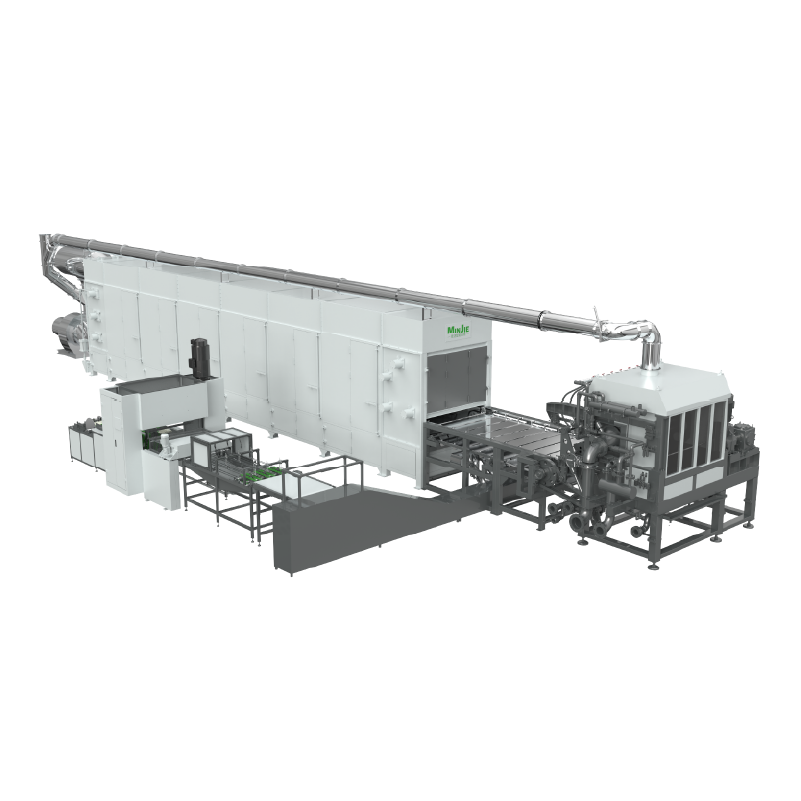

Pulp Molding Egg Tray Fruit Tray Production Line

Type:

Equipment introduction

| Item | Technical Parameter |

| Platen size |

1900mm*400mm/1600mm*400mm |

| Structure | Rotary Suction Forming + Multi-layer Dryer + Conveyor Stacking |

| Drying Method | Natural Gas, LPG,LNG, Thermal Oil (Needs some change in the heating system) or Steam (Needs some change in the heating system) |

| Feature | Capable of producing egg trays, fruit trays, fruit trays and some drinks trays |

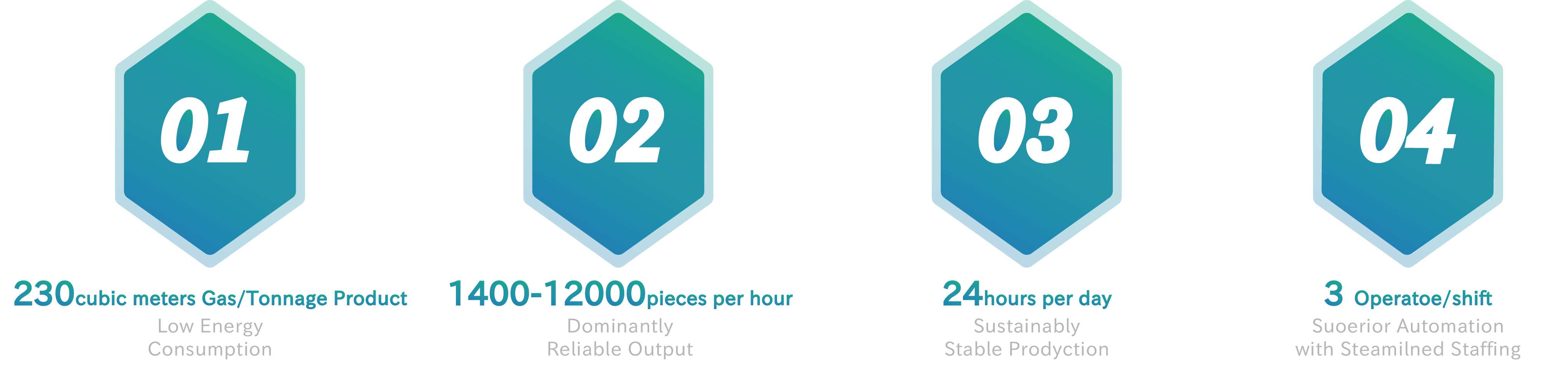

Equipment advantages

| Processing Point | Drive Method |

| Suction Former Work Station | Servo Motor+Precision Reducer |

| Oven Dryer Work Station | Servo Motor (sharing the same as the suction former) |

| Conveyor & Stacker | Servo Motor |

| Processing point | Parameter/Feature |

| Stiffness | adopting rack structure, increasing the overall machine stiffness |

| operation accuracy | adopting full mechanical structure to ensure accuracy |

| operation safety | based on CE requirement |

| pipeline design | optimized pipeline layout which makes the processing with higher stability |

| machine maintenance | reasonable and user-friendly design which makes it easy to do maintenance. |

| oven |

with a six-layer three-dimensional structure, optimizing space utilization using natural gas as a heat source to directly heat the air operating temperature is usually maintained at 220-250°C. with a circulation fan to realize the uniform flow of hot air in the drying oven from top to bottom bringing following characteristics: 1. High efficiency and energy saving, low operation cost and pollution-free 2. Intelligent temperature control system to ensure stable production 3. Fully automated operation, significantly improving efficiency 4. operational continuously all year round and not restricted by the external environment |

| Machine | Warranty Service | Component Description |

| Egg Tray Production Line | 3-year Warranty | Machine Racks, Oven Dryer Main Frame, Upper Platen, Down Platen, Pulp Tank, ect. |

| 1-year Warranty | Guiderails, Sliding Blocks, Cylinders, Pneumatic Components (not including push-in fittings, sealing parts), reducers, motors, electrical components, Oven Chain, Oven Tray, ect. | |

| Weary Part (Out of the warranty range) | Buttons, push-in fittings, vacuum skeleton hoses, sealing parts, heat insulation plates, ect. |

Equipment Video

Product Applications

Keywords:

Leave a Message

HOW CAN WE HELP YOU!

We understand the importance approaching each work integrally and believe in the power of simple and easy communication.

Minjie Eco-Machinery Technology Co., Ltd.

Factory

Tangxia Town, Pengjiang District, Jiangmen City, Guangdong, China

Operation Center

Lihe Science Park, Shishan Town, Nanhai District, Foshan City, Guangdong, China