WHAT WE OFFER

Machinery Solution Supplier

Learn MoreMold Solution Supplier

Learn MoreProduct Solution Supplier

Learn MoreIntegrated Production Line Solution

Learn MoreMAIN PRODUCTS

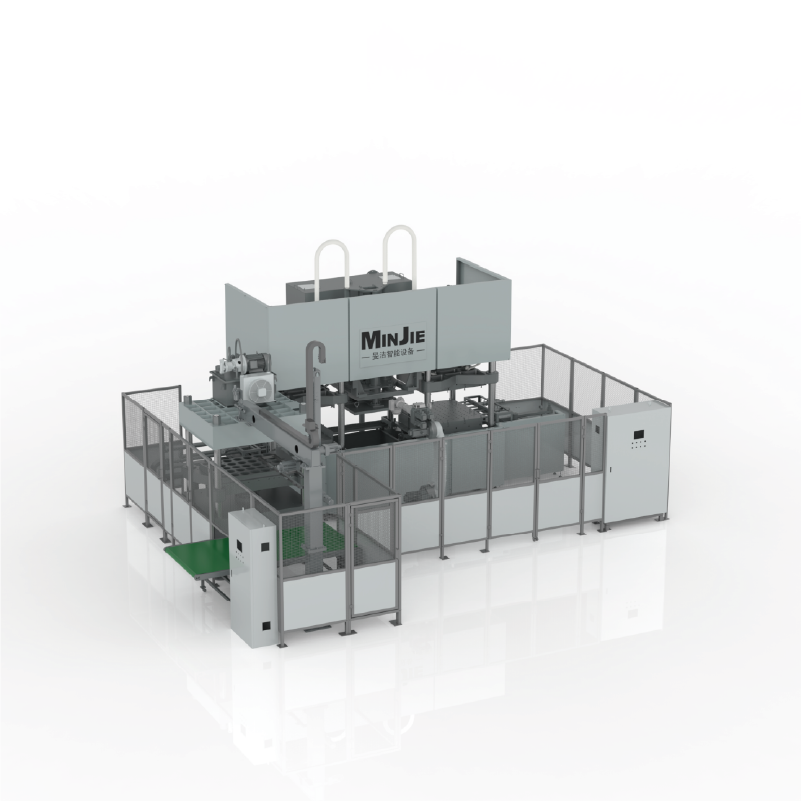

Full Automation Molded Fiber Tableware Machine MJDTN121-1210

Capable of making various food containers with general designs including clamshells, bowl, plates, trays and also with customized design with higher requirement // With output: 700-1000 kg/day (depending on exact designs, 700 kg/day for 9 inch round plate) // Platen size: 1200 mm *1000 mm

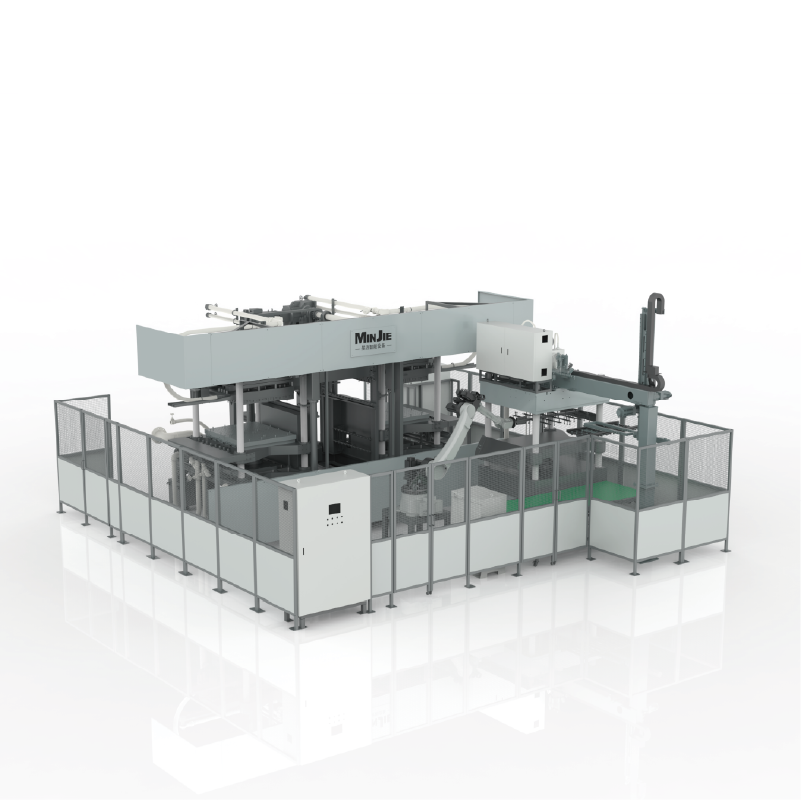

Full Automation Molded Fiber Cup & Cup Lid Machine MJCTN121-1210

Capable of making coffee cup lids with snap fit and fine-art industrial packages for 3C electronics, cosmetics // With output: 650-750 kg/day (≥140,000 pieces/day) // Platen size: 1200 mm *1000 mm

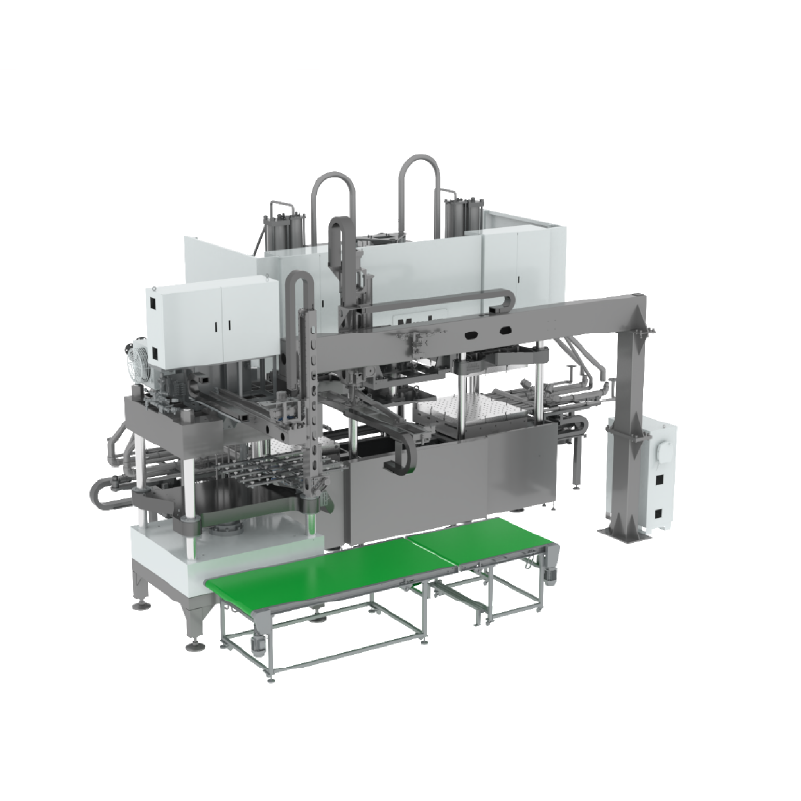

Full Automation Molded Fiber Tableware Machine MJDTN121-1210C

Structure: dig forming, two hot-press working stations and in-line trimming, and with no need to match with transfer mold to move wet product from forming station to hot-press station(s), beneficial to being higher in precision and more energy.

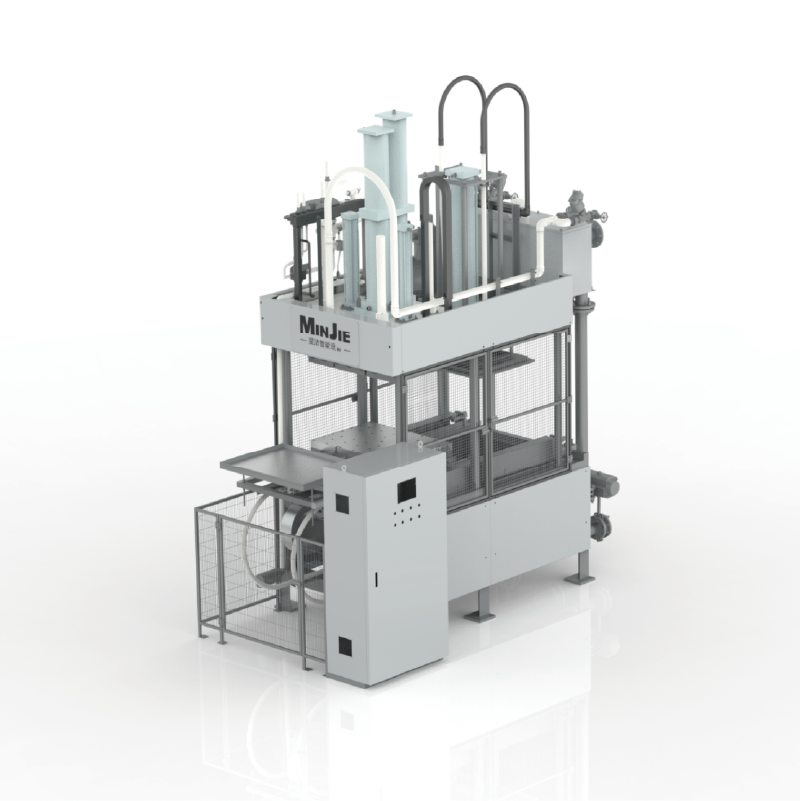

Molded Fiber Tableware Machine Mini Version MJDTN11-8060

Structure: dig forming, one hot press working station and off-line trimming

ABOUT MINJIE

Embodied with Dreams

Sailing/Making a Difference

Minjie Eco-Machinery Technology Co., Ltd. (short as “Minjie”), has been focusing on the evaluation and implementation of the overall planning for molded fiber project for many years, with company philosophy “Innovation, Technology, Dedication, Harmony”, targeting to provide clients with one-stop service. Minjie has its location in Jiangmen, Guangdong, China, covering an area of 20000㎡, with workshops for machinery and mold, covering function modules including molded fiber machinery manufacturing, electric automation, installation and commissioning, etc.

Learn MoreWork Experience

Talented Staffs

Modern Factory Area

Cooperative Partner

CASES

BLOG

Minjie | Win-Win Strategic Partnership with Partners Limited

Jun 18,2025

Minjie and Partners Limited formally signed a strategic cooperation agreement

Minjie Eco-Machinery Technology Co., Ltd.

Factory

Tangxia Town, Pengjiang District, Jiangmen City, Guangdong, China

Operation Center

Lihe Science Park, Shishan Town, Nanhai District, Foshan City, Guangdong, China