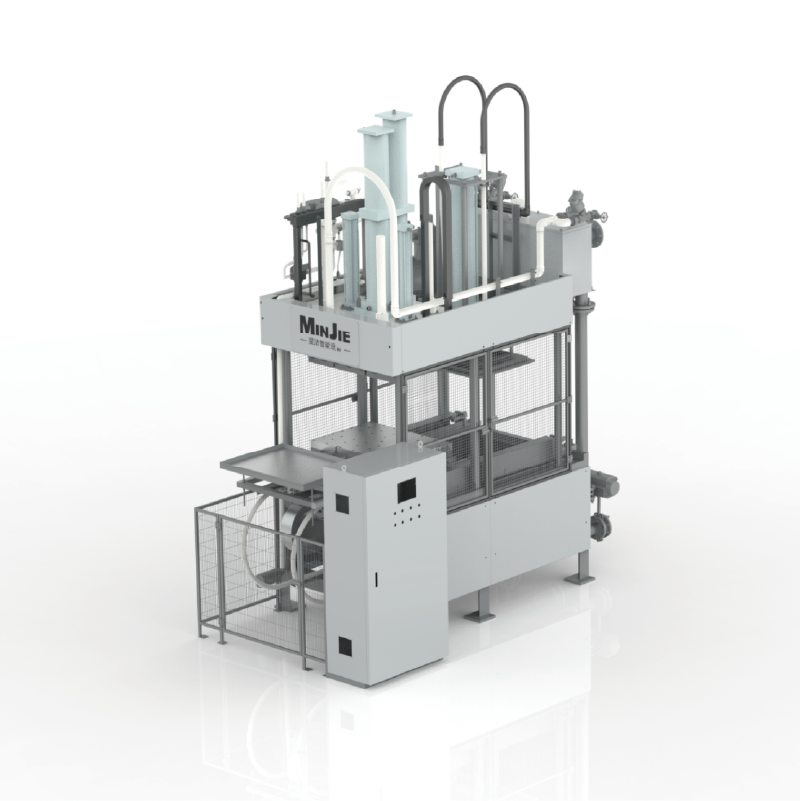

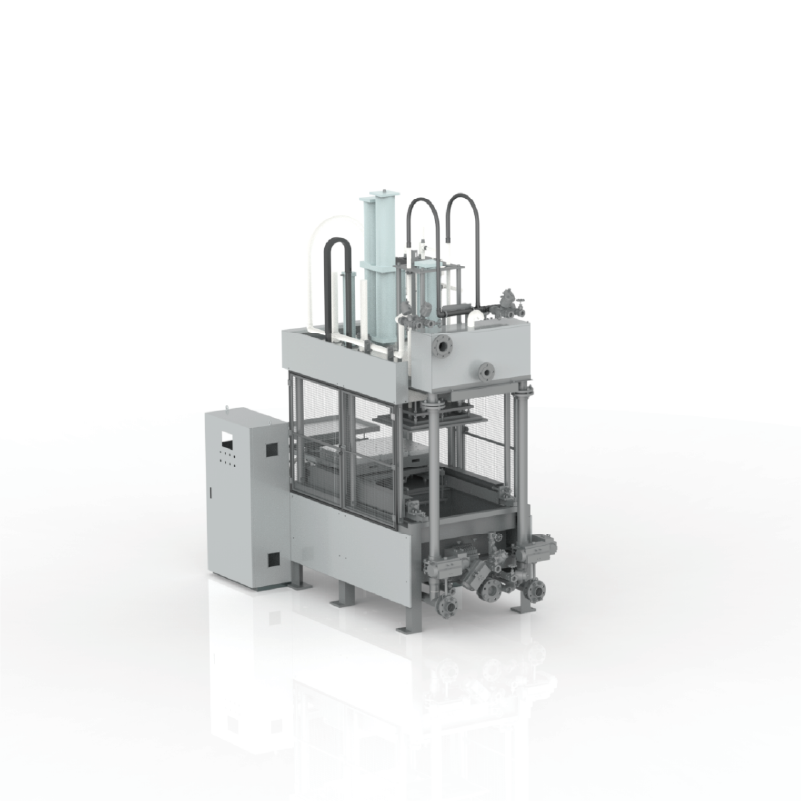

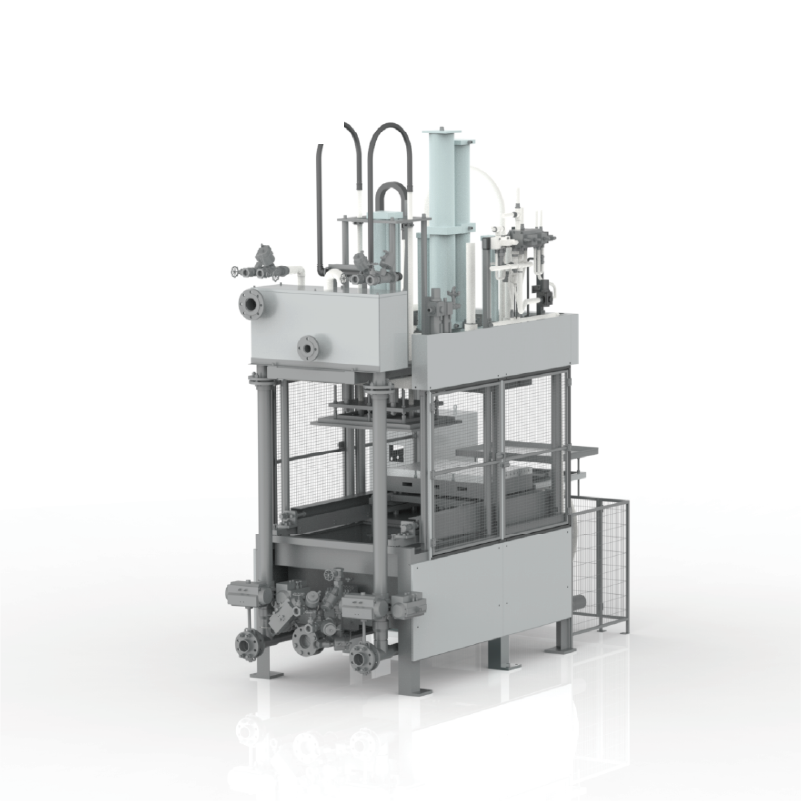

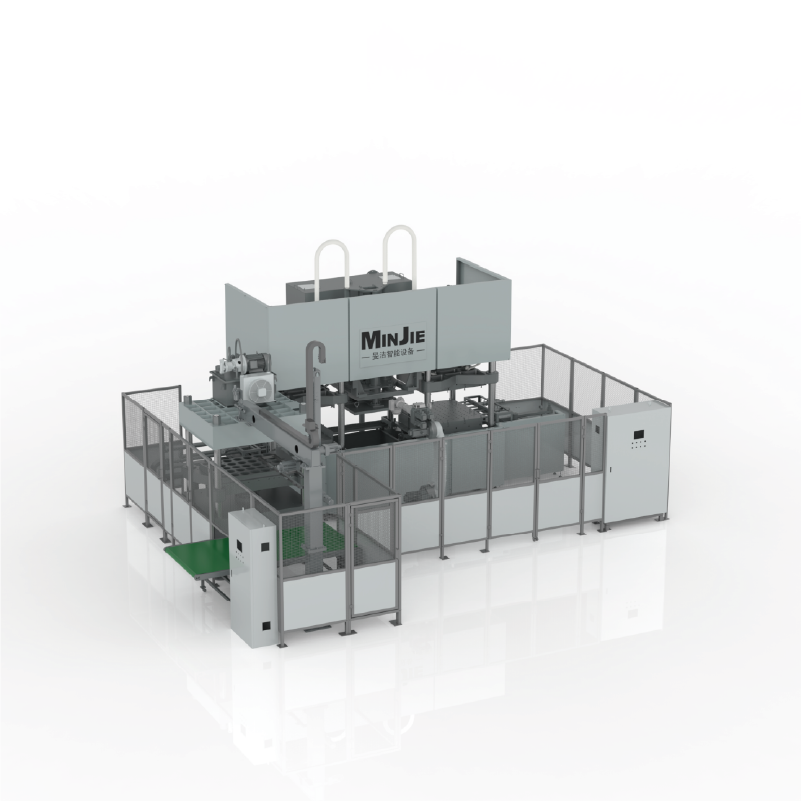

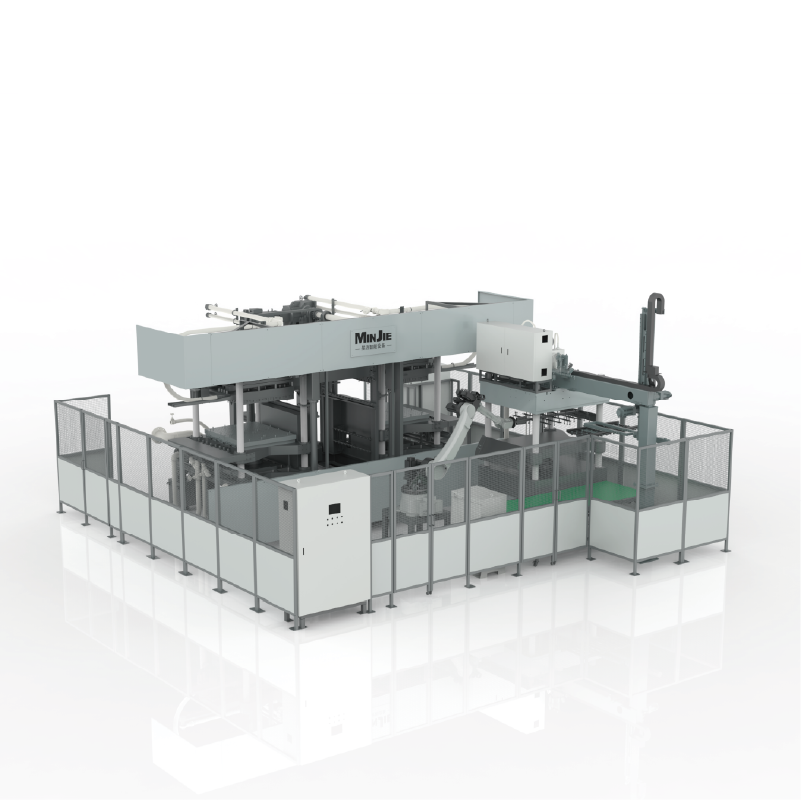

Molded Fiber Tableware Machine Mini Version MJDTN11-8060

Type:

Structure: dig forming, one hot press working station and off-line trimming

Leave Message

Equipment introduction

| Item | Technical Parameter |

| Platen size | 800 mm*600 mm |

| Structure | Suction Forming + Heat Press (one station) |

| Heat Power | Thermal Oil Heating or Electrical Heating |

| Rated Power | 0kw (thermal oil heating) or 30 kw (electrical heating) |

| Outer Size | 3000 mm*1600 mm*3450 mm |

| Weight | 4.6 tons |

| Average Output | 150-200 kgs/day |

| Vacuum Setting | 5-8 m³/min |

| Air Setting | 1.5-2 m³/min |

| Forming Type | Dig Suction |

| Main Drive | Pneumatic (Suction Forming) + Pneumatic (Heat Press) |

| Feature | Capable of making food packgings with General design or with fit sealing functions. |

Equipment advantages

| Processing Point | Drive Method |

| Suction Forming Work Station | Servo Motor+Precision Reducer |

| Extrusion Work Station | Servo Motor+Precision Reducer |

| Heat Press Station | Hydraulic (Hydraulic Servo,60 tonnage Force) |

| Multi-joint Robot | Servo Motor+Precision Reducer |

| Trimming Work Station | Hydraulic (Hydraulic Servo,60 tonnage Force) |

| Stacking/Conveyor/Trusser Mechanism | Servo Motor+Precision Reduce |

| Wet Product Transfer (Suction Forming-->Left Heat Press) (Suction Forming-->Right Heat Press) | Servo Motor+Precision Reduce |

| Processing point | Parameter/Feature |

| Stiffness | adopting rack structure, increasing the overall machine stiffness |

| operation accuracy | adopting full mechanical structure to ensure accuracy |

| operation safety | based on CE requirement |

| processing adaptability | with rotary suction, equipped with extrusion function (with heat generally), and also with upper heat press mold to work as transfer mold, which brings higher adaptability of packaging, especially those with high requirement and value. |

| pipeline design | optimized pipeline layout which makes the processing with higher stability |

| mold maintenance | with relatively low heating temperature (170-190℃) which lengths the hole-cleaning duration, and with reasonably long mold cleaning period. |

| machine maitenance | reasonable and user-friendly design which makes it easy to do maintenance |

| Machine | Warranty Service | Component Description |

| Tableware Machine | 3-year Warranty | Machine Racks, Upper Platen, Down Platen, Pulp Tank, etc. |

| 1-year Warranty | Guide rails, Sliding Blocks, Cylinders, Pneumatic Components (not including push-in fittings, sealing parts), reducers, motors, electrical components, etc. | |

| Weary Part (Out of the warranty range) | Buttons, push-in fittings, vacuum skeleton hoses, sealing parts, heat insulation plates, etc. |

Equipment Video

Product Applications

Representative Case

Keywords:

pulp based food packaging making machine

molded fiber food packaging making machine

pulp molding food packaging making machine

Representative Case

disposable tableware making machine

tableware making machine

Leave a Message

HOW CAN WE HELP YOU!

We understand the importance approaching each work integrally and believe in the power of simple and easy communication.

Relate Product

Minjie Eco-Machinery Technology Co., Ltd.

Factory

Tangxia Town, Pengjiang District, Jiangmen City, Guangdong, China

Operation Center

Lihe Science Park, Shishan Town, Nanhai District, Foshan City, Guangdong, China