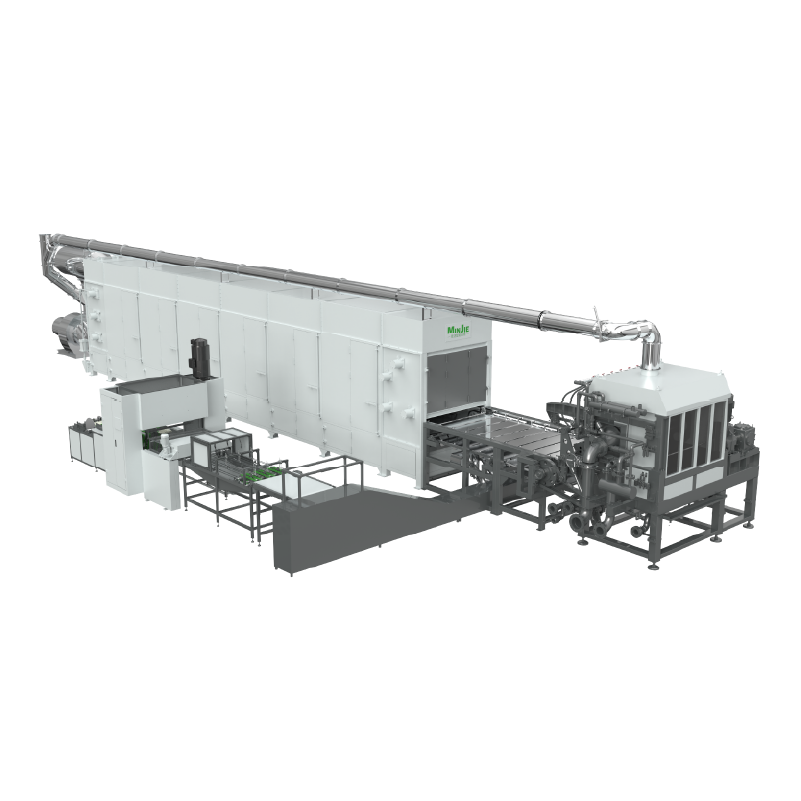

Pulp Molding Egg Box Egg Tray Egg Carton Cup Carrier Production Line MJEB-5400

Type:

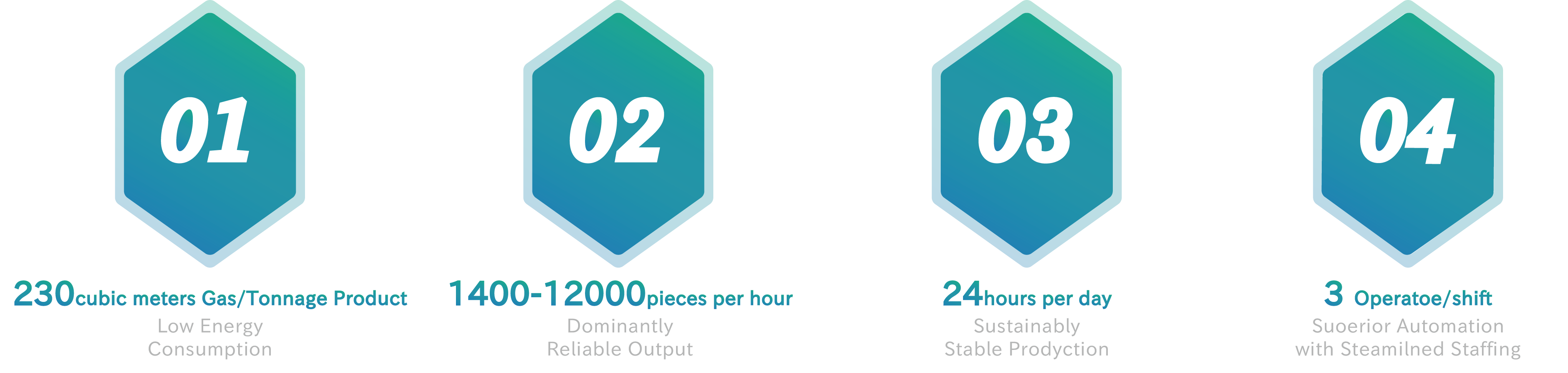

To make Pulp molding Egg Box Packaging and Cup Carrier / with output capacity ranging from 5400 pieces/hr / with energy consumption around 210-230 cubic meter natural gas per tonnage package

Leave Message

Equipment introduction

| Item | Technical Parameter |

| Platen size | 1900mm*400mm/1600mm*400mm |

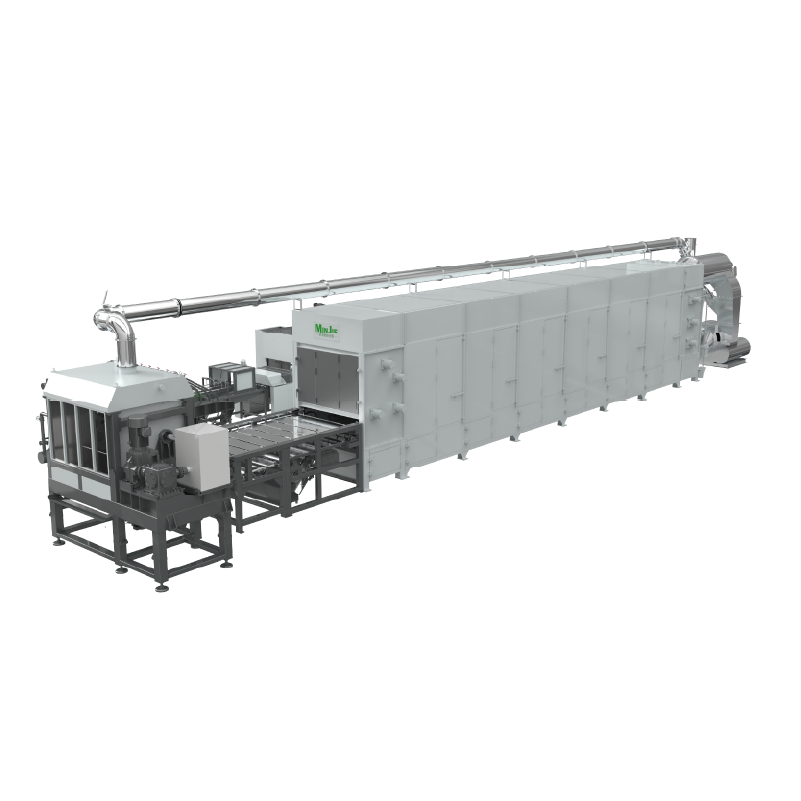

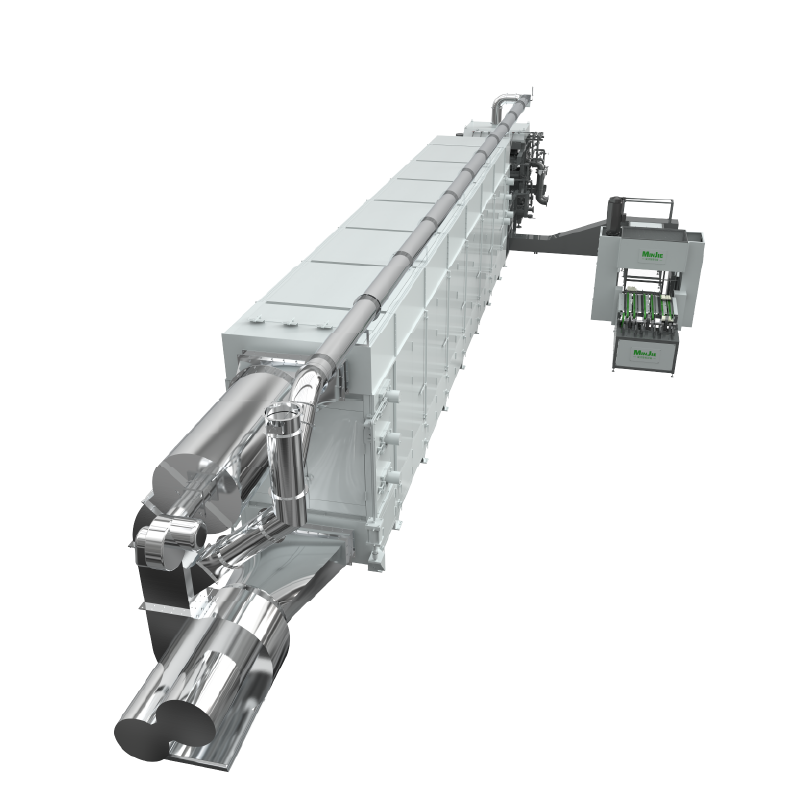

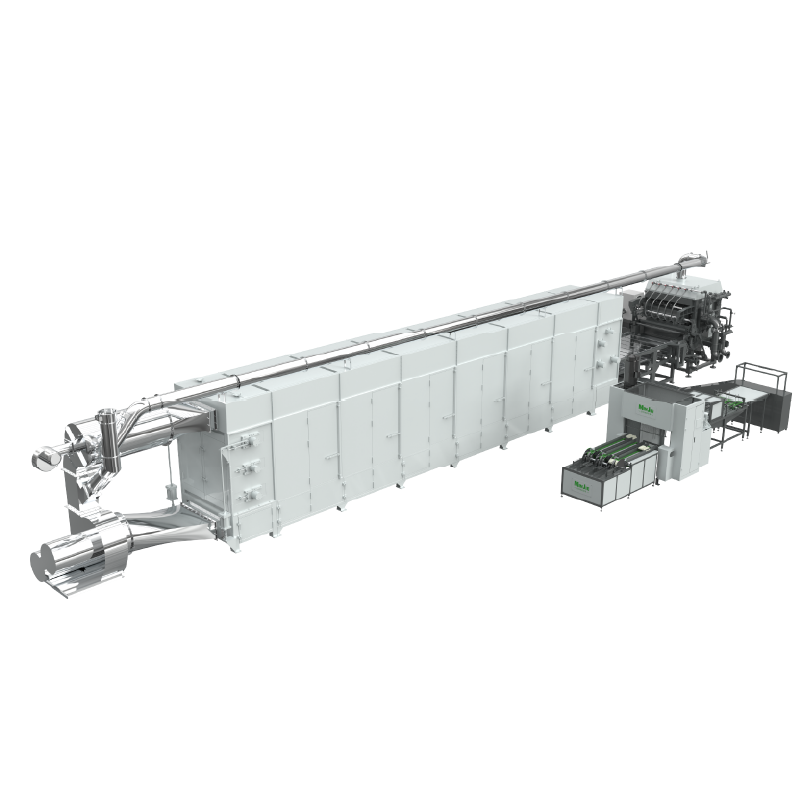

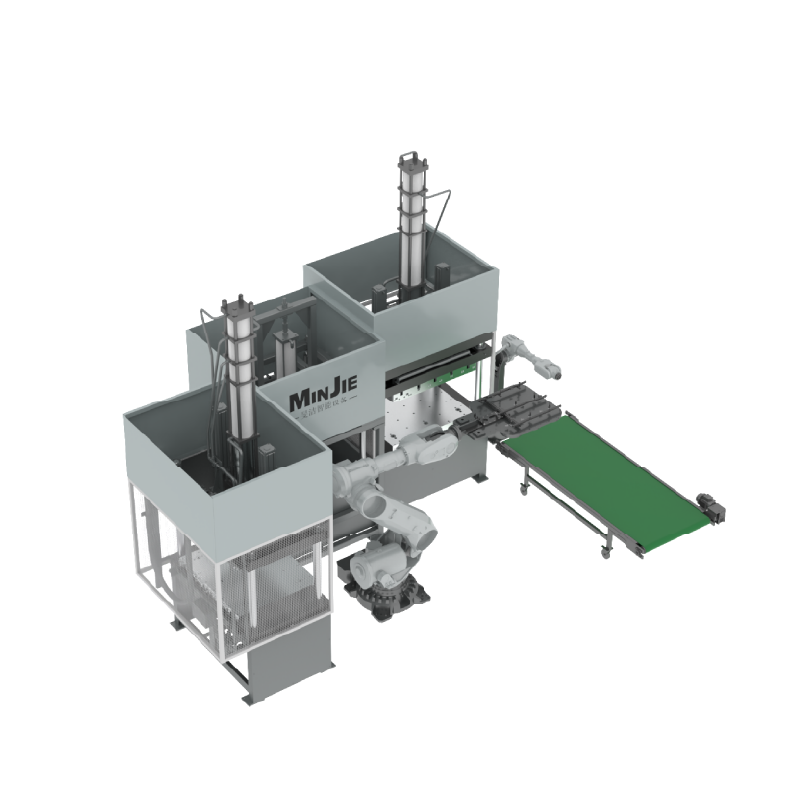

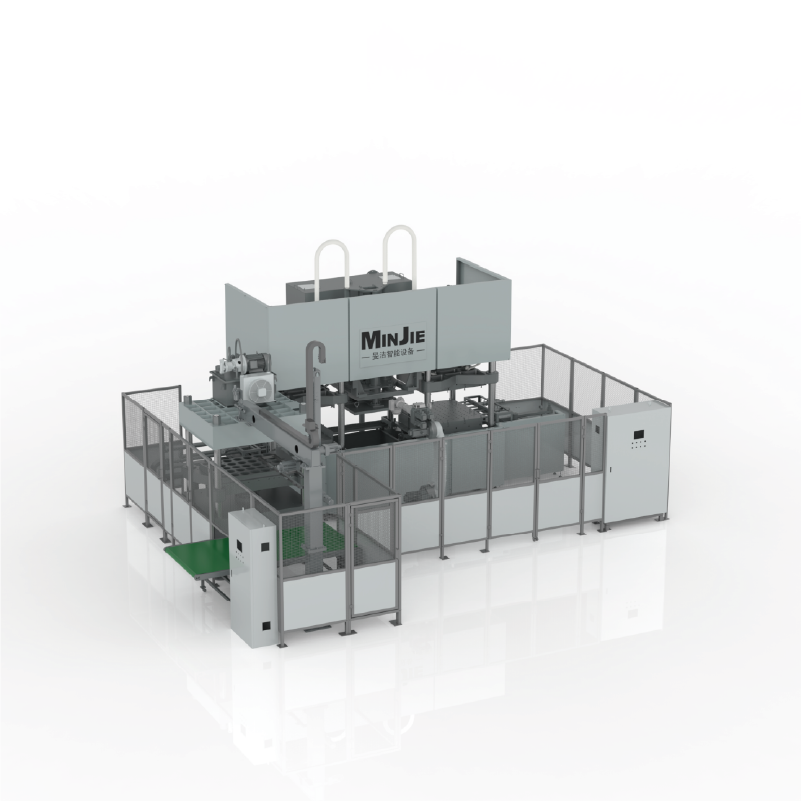

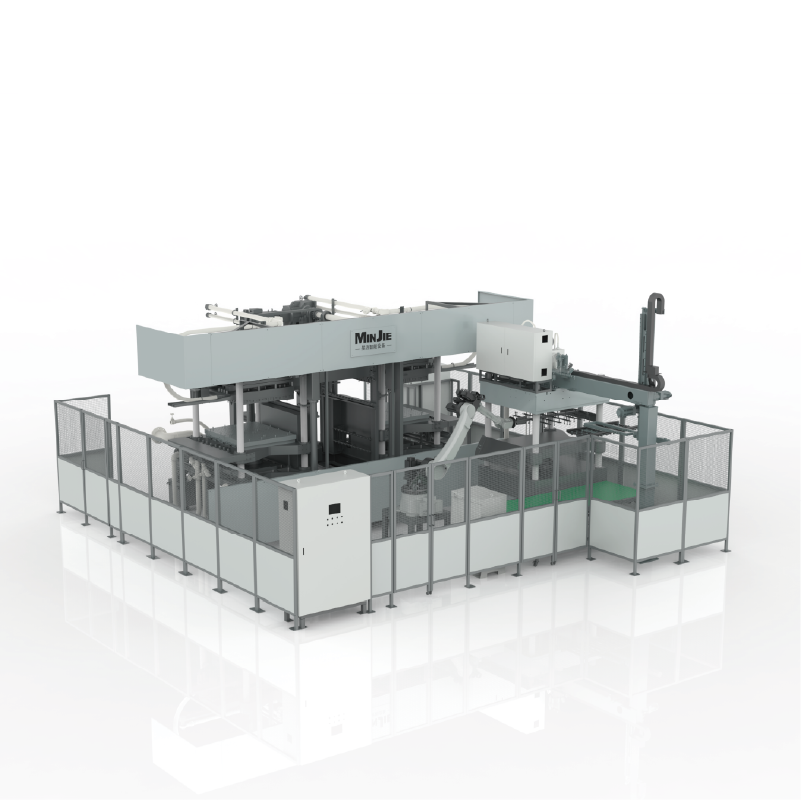

| Structure | Rotary Suction Forming + Multi-layer Dryer + Online Heat Shaping + Conveyor Stacking |

| Drying Method | Natural Gas,LPG,LNG,Thermal Oil or Steam |

| Feature | Capable of producing egg boxes and cup carriers |

Equipment advantages

| Processing Point | Drive Method |

| Suction Forming Station | Servo Motor+Precision Reducer |

| Oven Dryer | share the same as the Suction Forming Section |

| Heat Press Station | Hydraulic (Hydraulic Servo,40 tonnage Force) |

| Stacking | Servo Motor |

| Processing point | Parameter/Feature |

| Stiffness | adopting rack structure, increasing the overall machine stiffness |

| operation accuracy | adopting full mechanical structure to ensure accuracy |

| operation safety | based on CE requirement |

| processing adaptability | with rotary suction, multiple layer oven dryer, and also with online heat shaping, which brings higher efficiency compared with the traditional way |

| pipeline design | optimized pipeline layout which makes the processing with higher stability |

| machine maitenance | reasonable and user-friendly design which makes it easy to do maintenance |

| Machine | Warranty Service | Component Description |

| Egg Box Packaging Production Line | 3-year Warranty | Machine Racks, Upper Platen, Down Platen, Pulp Tank, etc. |

| 1-year Warranty | Guide rails, Sliding Blocks, Cylinders, Pneumatic Components (not including push-in fittings, sealing parts), reducers, motors, electrical components, etc. | |

| Weary Part (Out of the warranty range) | Buttons, push-in fittings, vacuum skeleton hoses, sealing parts, heat insulation plates, etc. |

Equipment Video

| Description of the video: Here is the full automation moulded pulp egg box cup carrier prodution system with 10-cavity moulded pulp egg box packaging being produced and an hourly output of 5400 pieces (based on 15 drops per minute as the running speed,with online heat shaping involved) |

| High-Volume Solution: Perfect for mass-producing pulp moulded egg boxes, cup carriers and similar items. Key Benefits: Boosts efficiency, expands output, and supports full automation. Best For: Companies scaling up while ensuring consistent quality. |

| Product Variety: Makes standard, uniform pulp molded pulp packages like egg cartons (10/12/15/18/6+6-cavity,for chicken, duck, goose, and quail), cup carriers (2/2+2/4-cavity for coffee cups). Eco-Friendly Inputs: Utilizes a variety of recycled paper materials, including cardboard cartons, discarded books and newspapers, printing scrap, and even previously used egg cartons. |

Product Applications

Representative Case

Keywords:

egg box machine

pulp molding egg carton production line

pulp molding egg tray production line

Thermoformed molded fiber products

egg tray making machine

paper pulp egg tray making machine

pulp molding machine

Leave a Message

HOW CAN WE HELP YOU!

We understand the importance approaching each work integrally and believe in the power of simple and easy communication.

Relate Product

Minjie Eco-Machinery Technology Co., Ltd.

Factory

Tangxia Town, Pengjiang District, Jiangmen City, Guangdong, China

Operation Center

Lihe Science Park, Shishan Town, Nanhai District, Foshan City, Guangdong, China