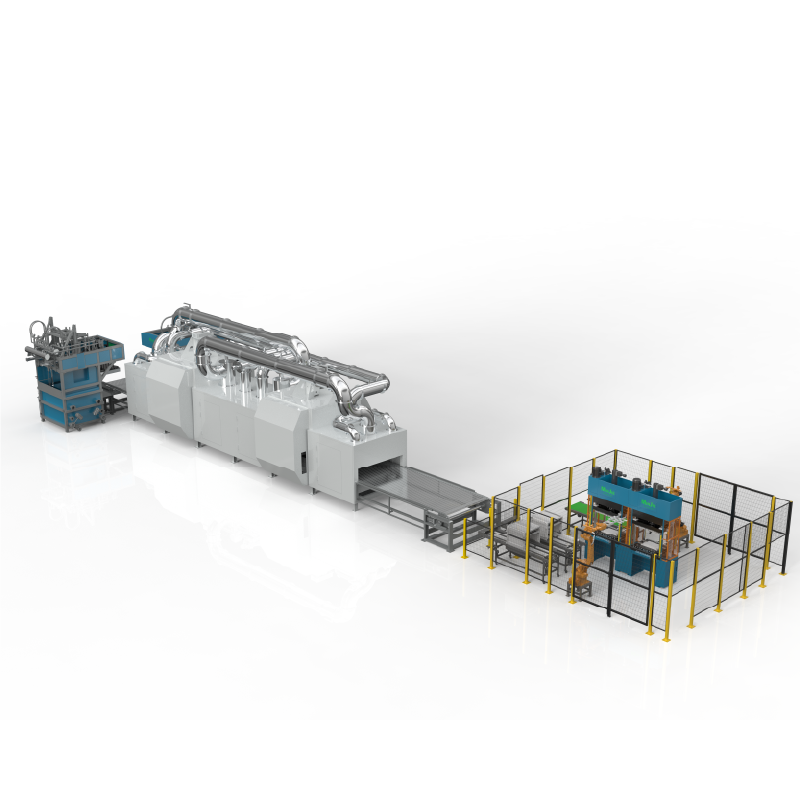

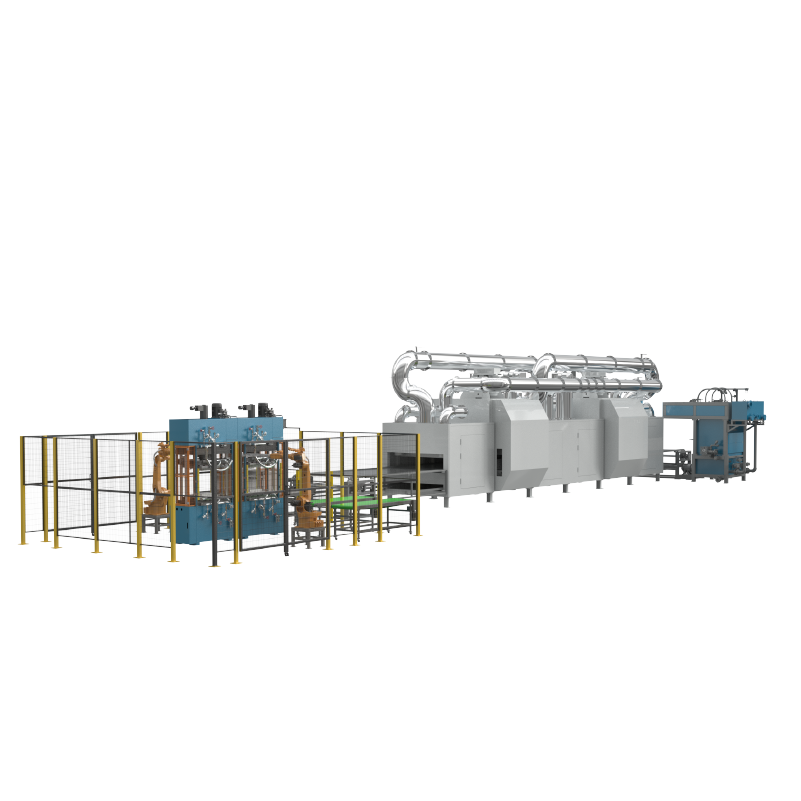

High Efficiency Oven Dryer Pulp Molding Industrial Package IPP-300

Type:

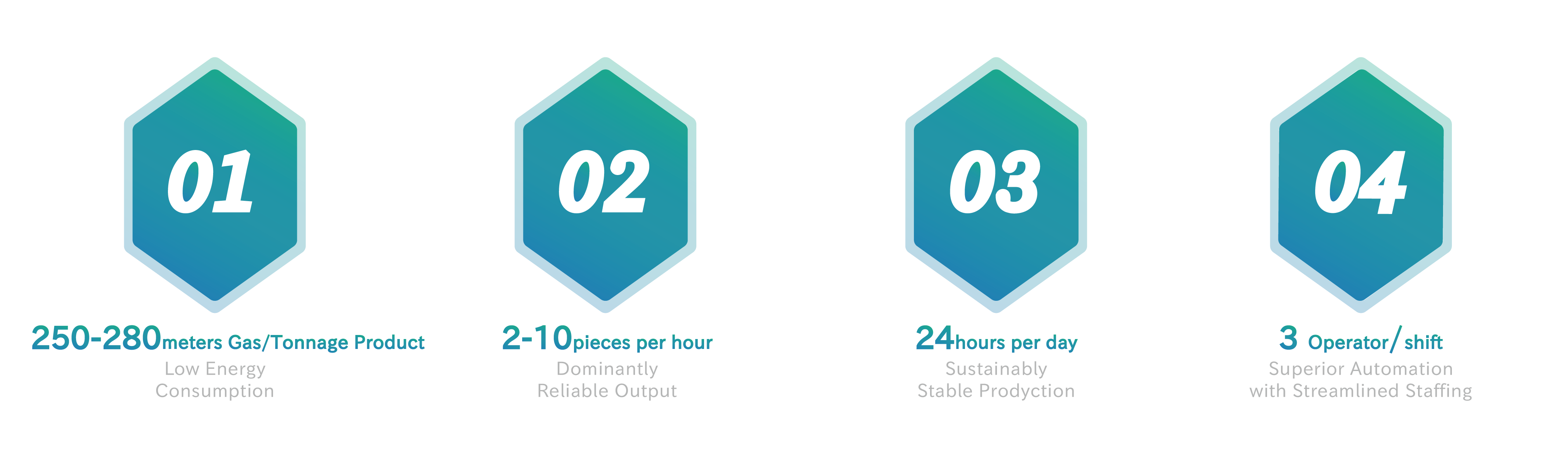

with dig forming, high efficient oven dryer and finished product collections and Off-line heat shaping / output ranging from 2 tons to 10 tons (depending on the quantities of forming and heat shaping, the length of oven dryer) / natural gas consumption: 250-280 tons per tonnage (depending on the package designs)

Leave Message

Equipment introduction

| Item | Technical Parameter |

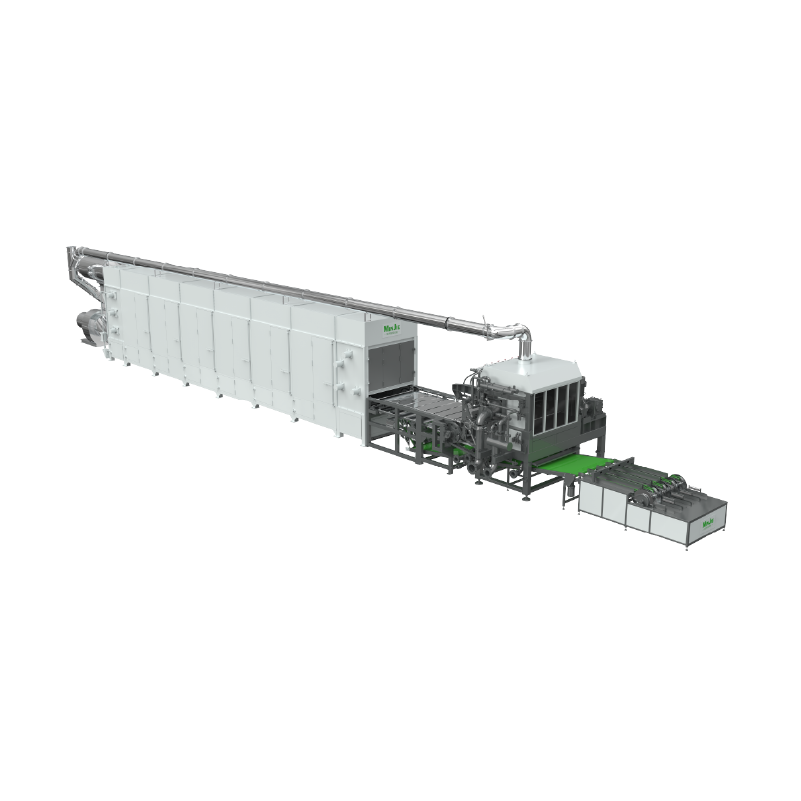

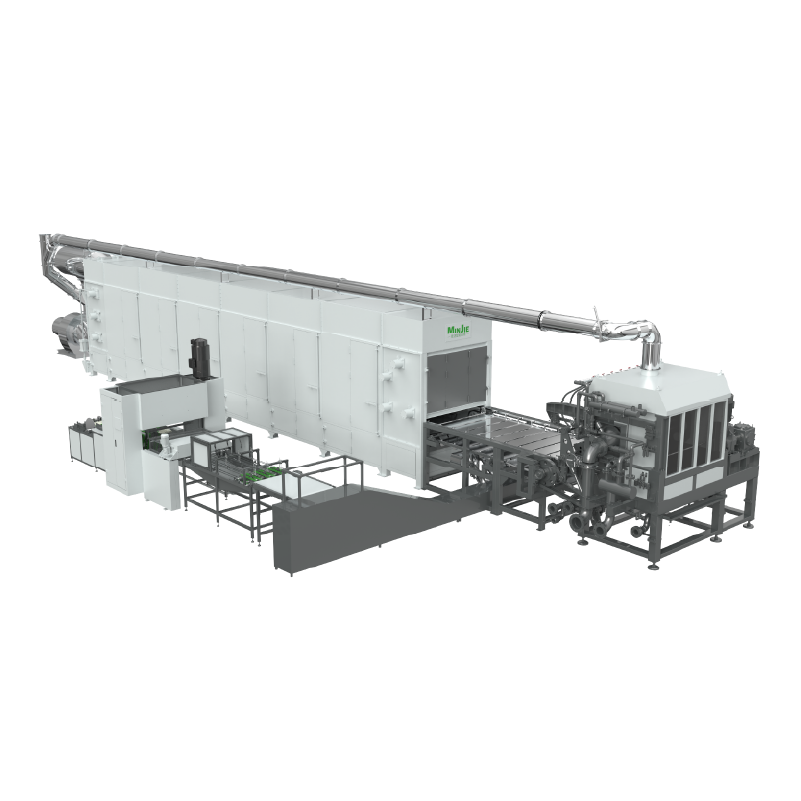

| Platen size |

Suction Former: 1200mm*800mm Oven Dryer (Tunnel Part): 13200mm*1600mm Heat Shaper: 800mm*600mm |

| Structure | Reciprocating Forming + Single-layer High Efficiency Oven Dryer + Online Heat Shaping |

| Drying Method | Natural Gas, LPG, LNG |

| Feature | Capable of producing various industrial protective packagings |

Equipment advantages

| Processing Point | Drive Method |

| Suction Former Work Station | Servo Motor+Pneumatic(Air-liquid Booster) |

| Oven Dryer Work Station | Servo Motor+Prequency Motor |

| Multi-joint Robot | Servo Motor+Precision Reducer |

| Online Heat Shaper Work Station | Hydraulic (Hydraulic Servo,60 tonnage Force) |

| Finished Product Conveyor | Servo Motor+Prequency Motor |

| Processing point | Parameter/Feature |

| Stiffness | adopting rack structure, increasing the overall machine stiffness |

| operation accuracy | adopting full mechanical structure to ensure accuracy |

| operation safety | based on CE requirement |

| pipeline design | optimized pipeline layout which makes the processing with higher stability |

| machine maintenance | reasonable and user-friendly design which makes it easy to do maintenance |

| oven dryer advantage |

|

| Machine | Warranty Service | Component Description |

| Industrial Protective Package Production Line | 3-year Warranty | Machine Racks, Oven Dryer Main Frame Body, Upper Platen, Down Platen, Pulp Tank, ect. |

| 1-year Warranty | Guiderails, Sliding Blocks, Cylinders, Pneumatic Components (not including push-in fittings, sealing parts), reducers, motors, electrical components, oven drive chain, oven tray, ect. | |

| Weary Part (Out of the warranty range) | Buttons, push-in fittings, vacuum skeleton hoses, sealing parts, heat insulation plates, ect. |

Equipment Video

Product Applications

Representative Case

Keywords:

pulp molding industrial package production line

pulp molding production line

pulp molding machine

egg tray machine

egg tray making machine

Leave a Message

HOW CAN WE HELP YOU!

We understand the importance approaching each work integrally and believe in the power of simple and easy communication.

Relate Product

Minjie Eco-Machinery Technology Co., Ltd.

Factory

Tangxia Town, Pengjiang District, Jiangmen City, Guangdong, China

Operation Center

Lihe Science Park, Shishan Town, Nanhai District, Foshan City, Guangdong, China